Frequently Asked Questions

Tech Tips

What rpm are Gaterman Products automotive lifters good for?

We typically recommend 6500 rpm as a practical upper limit. However, with the right cam profile and valve train components, we have customers that turn them over 7500 rpm. We don't recommend high rpm operation for sustained, continuous use.

We typically recommend 6500 rpm as a practical upper limit. However, with the right cam profile and valve train components, we have customers that turn them over 7500 rpm. We don't recommend high rpm operation for sustained, continuous use.

What's the seat height of your automotive lifters?

The seat height shown is the distance from the bottom of the roller to the top of a 5/16'' (.3125") dia. ball in the pushrod seat. The seat height has a tolerance stack of +/- .012".

The seat height shown is the distance from the bottom of the roller to the top of a 5/16'' (.3125") dia. ball in the pushrod seat. The seat height has a tolerance stack of +/- .012".

What is meant by "extended body" on your GP1012 and GP1014 drop in replacement lifters?

When the total lift is increased on a cam lobe for a conventional pushrod V8 engine, the base circle diameter of the cam lobe is reduced. As a result, the lifter will drop further into the lifter bore. "Extended body" means the part of the lifter that engages the factory anti-rotation hardware is longer. This is done to allow the lifter to accommodate higher lift camshafts before the lifter dis-engages the anti-rotation hardware.

Since the lifter is physically longer, it may require the removal of the cylinder heads on the Ford 5.0 and 302 V8. It's not required on the Ford 351W V8. On the GM LS V8, the cylinder heads must be removed for any lifter swap.

When the total lift is increased on a cam lobe for a conventional pushrod V8 engine, the base circle diameter of the cam lobe is reduced. As a result, the lifter will drop further into the lifter bore. "Extended body" means the part of the lifter that engages the factory anti-rotation hardware is longer. This is done to allow the lifter to accommodate higher lift camshafts before the lifter dis-engages the anti-rotation hardware.

Since the lifter is physically longer, it may require the removal of the cylinder heads on the Ford 5.0 and 302 V8. It's not required on the Ford 351W V8. On the GM LS V8, the cylinder heads must be removed for any lifter swap.

What is the roller diameter of your lifters?

The roller bearing outside diameter of all Gaterman Products hydraulic roller lifters is .700", with the exception of the Harley-Davidson® Evolution® motorcycle lifter, which is .945".

The roller bearing outside diameter of all Gaterman Products hydraulic roller lifters is .700", with the exception of the Harley-Davidson® Evolution® motorcycle lifter, which is .945".

Why don't you use a larger diameter roller?

In order to fit in the lifter bore, the size of the roller has to be balanced between the outside diameter of the roller and the roller width. We have found that for for hydraulic roller applications, it's more advantageous to have a wide roller to deter both roller bearing axle wear and roller tracking on the cam lobes.

In order to fit in the lifter bore, the size of the roller has to be balanced between the outside diameter of the roller and the roller width. We have found that for for hydraulic roller applications, it's more advantageous to have a wide roller to deter both roller bearing axle wear and roller tracking on the cam lobes.

Is the face of the roller flat?

No, typically not. Actually the roller face has a large compound spherical radius. This is done to accommodate any mis-alignment of the rollers and cam lobe faces. The sources of the mis-alignment are numerous, including cam lobe taper, lifter bore mis-alignment to camshaft bore, and roller axle mis-alignment. Without the roller face radius, edge riding of the roller on the cam lobe would be likely, resulting in cam lobe and roller failure.

No, typically not. Actually the roller face has a large compound spherical radius. This is done to accommodate any mis-alignment of the rollers and cam lobe faces. The sources of the mis-alignment are numerous, including cam lobe taper, lifter bore mis-alignment to camshaft bore, and roller axle mis-alignment. Without the roller face radius, edge riding of the roller on the cam lobe would be likely, resulting in cam lobe and roller failure.

Why do your lifters have multiple oil holes?

In order to refill the lifter after each rotation cycle, oil must be made available to the inside of the lifter. Multiple oil holes allow for a sufficient and uninterrupted supply despite the possibility of air bubbles or debris in the oil.

In order to refill the lifter after each rotation cycle, oil must be made available to the inside of the lifter. Multiple oil holes allow for a sufficient and uninterrupted supply despite the possibility of air bubbles or debris in the oil.

Your drop in lifters have small oil holes on the flats. What are they for and do they negatively affect my engine's oil pressure?

The oil holes are there to lubricate the surface where the OE anti-rotation hardware rubs the lifter body. As a result, friction and wear are reduced. The oil that feeds those holes is bled off and would go into the sump anyway, so it has no impact on your oil pressure. We simply re-direct it to the interface where it is needed.

The oil holes are there to lubricate the surface where the OE anti-rotation hardware rubs the lifter body. As a result, friction and wear are reduced. The oil that feeds those holes is bled off and would go into the sump anyway, so it has no impact on your oil pressure. We simply re-direct it to the interface where it is needed.

Are link-bar style hydraulic roller lifters inherently noisier than OE style drop-in lifters?

Typical performance upgrades including high lift camshafts, roller rockers, and increased spring pressure can result in increased valve train noise. But, all other things being equal, a link bar lifter is likely to be slightly noisier than an OE style drop-in lifter just by virtue of the link bar. Due to production tolerances, there must be a certain amount of clearance between the link bar, the lifter body, and the fastener (bolt or rivet). This clearance can allow the link bar to rattle during operation. Since the roller faces are typically crowned to prevent edge riding on the cam lobes, the lifters often oscillate slightly as they reciprocate in the bores. This can also cause a slight amount of noise. By controlling tolerances, we can reduce the link bar clearance in order to minimize the noise, but binding must be avoided. The is particularly important in big block Chevy V8 applications. Since the intake and exhaust lifter bores aren’t in line, the link bar to body clearance is constantly changing as the lifters move up and down in the bores. In addition, the link bars can’t be flat and straight due to the lifter bore geometry, so more clearance is required to prevent binding at the extremes of the lifter travel. For a high quality link bar hydraulic roller lifter, any additional valve train noise is inherent to the link bar style design, not the quality of the lifter itself.

Typical performance upgrades including high lift camshafts, roller rockers, and increased spring pressure can result in increased valve train noise. But, all other things being equal, a link bar lifter is likely to be slightly noisier than an OE style drop-in lifter just by virtue of the link bar. Due to production tolerances, there must be a certain amount of clearance between the link bar, the lifter body, and the fastener (bolt or rivet). This clearance can allow the link bar to rattle during operation. Since the roller faces are typically crowned to prevent edge riding on the cam lobes, the lifters often oscillate slightly as they reciprocate in the bores. This can also cause a slight amount of noise. By controlling tolerances, we can reduce the link bar clearance in order to minimize the noise, but binding must be avoided. The is particularly important in big block Chevy V8 applications. Since the intake and exhaust lifter bores aren’t in line, the link bar to body clearance is constantly changing as the lifters move up and down in the bores. In addition, the link bars can’t be flat and straight due to the lifter bore geometry, so more clearance is required to prevent binding at the extremes of the lifter travel. For a high quality link bar hydraulic roller lifter, any additional valve train noise is inherent to the link bar style design, not the quality of the lifter itself.

What is meant by "leakdown"?

Leakdown (also known as bleed rate) refers to the rate at which the piston inside the lifter, which is under the pushrod socket, is depressed under load. The outside diameter of the piston is precision ground and fitted to the i.d. of the lifter body which is also precision ground. The total clearance between those two diameters is less than 0.0002". It's the rate at which the engine oil leaks by these surfaces that controls how quickly the piston/pushrod socket moves in the bore of the lifter body under the force from the valve train. Leakdown is typically measured in time versus distance traveled by the piston under a certain constant force. The test is performed under controlled conditions using proprietary fixtures and a laboratory grade test fluid.

Leakdown (also known as bleed rate) refers to the rate at which the piston inside the lifter, which is under the pushrod socket, is depressed under load. The outside diameter of the piston is precision ground and fitted to the i.d. of the lifter body which is also precision ground. The total clearance between those two diameters is less than 0.0002". It's the rate at which the engine oil leaks by these surfaces that controls how quickly the piston/pushrod socket moves in the bore of the lifter body under the force from the valve train. Leakdown is typically measured in time versus distance traveled by the piston under a certain constant force. The test is performed under controlled conditions using proprietary fixtures and a laboratory grade test fluid.

Can I make your hydraulic roller lifters operate like solid roller lifters by bottoming the preload adjustment?

No, definitely not. There are oil reliefs inside the lifter body which will properly distribute the oil in the lifter when the lifter is correctly adjusted. Bottoming the components may cause mis-alignment of the passages resulting in engine oil pressure loss.

No, definitely not. There are oil reliefs inside the lifter body which will properly distribute the oil in the lifter when the lifter is correctly adjusted. Bottoming the components may cause mis-alignment of the passages resulting in engine oil pressure loss.

Can I use your hydraulic roller lifters on my hydraulic flat tappet camshaft?

No, you can't. Nearly all flat tappet hydraulic camshafts on the market today are constructed of hardenable cast iron. Due to the relatively low elasticity and hardness of cast iron in its heat treated state, it's highly prone to spalling as a result of the high unit loading of a roller lifter interface. This is especially true in the areas of tight radius of curvature around the nose of the lobe. In addition, nearly all overhead valve flat tappet camshafts have taper ground into the lobes. Edge riding of the roller will result in premature cam lobe failure when used with a flat tappet camshaft. In addition, the lobe shape of a flat tappet camshaft will yield very low duration and poor performance when used with a roller lifter. It's really not a good idea.

No, you can't. Nearly all flat tappet hydraulic camshafts on the market today are constructed of hardenable cast iron. Due to the relatively low elasticity and hardness of cast iron in its heat treated state, it's highly prone to spalling as a result of the high unit loading of a roller lifter interface. This is especially true in the areas of tight radius of curvature around the nose of the lobe. In addition, nearly all overhead valve flat tappet camshafts have taper ground into the lobes. Edge riding of the roller will result in premature cam lobe failure when used with a flat tappet camshaft. In addition, the lobe shape of a flat tappet camshaft will yield very low duration and poor performance when used with a roller lifter. It's really not a good idea.

Can I use your hydraulic roller lifters with my solid roller camshaft?

It will mechanically function to some degree, but it's not recommended. Since the normal clearance ramps on a hydraulic roller cam lobe are quite low compared to a solid roller, the engine will "see" a much longer duration valve motion. So, there will be decreased vacuum and very sluggish low end performance. In addition, some really long duration solid roller clearance ramps may be confused with base circle runout by the hydraulic lifter mechanism. This will result in very poor engine performance.

It will mechanically function to some degree, but it's not recommended. Since the normal clearance ramps on a hydraulic roller cam lobe are quite low compared to a solid roller, the engine will "see" a much longer duration valve motion. So, there will be decreased vacuum and very sluggish low end performance. In addition, some really long duration solid roller clearance ramps may be confused with base circle runout by the hydraulic lifter mechanism. This will result in very poor engine performance.

Application Information

Do your small block Ford V8 retrofit lifters (GP1003) require a special small base circle camshaft?

No, they don't. During the early development of roller lifters for non-roller small block Ford V8 engines, the stock Ford factory roller lifters were used in conjunction with special hardware and a small base circle camshaft. We modified the design of our GP1003 retrofit roller lifter body to enable it to work with standard size base circle camshafts in the early small block Fords that originally used flat-faced lifters. No special small base circle camshafts are required.

No, they don't. During the early development of roller lifters for non-roller small block Ford V8 engines, the stock Ford factory roller lifters were used in conjunction with special hardware and a small base circle camshaft. We modified the design of our GP1003 retrofit roller lifter body to enable it to work with standard size base circle camshafts in the early small block Fords that originally used flat-faced lifters. No special small base circle camshafts are required.

Will your small block Ford V8 retrofit lifters (GP1003) work with later model blocks that originally came from the factory with hydraulic roller lifters? Later model Ford and some aftermarket blocks have raised lifter bore bosses to accommodate the extra anti-rotation hardware when using factory style roller lifters. Our GP1003 retrofit lifters will work in these blocks with certain limitations to the cam base circle sizes. These limitations are to insure the tie bar doesn't contact the top of the lifter bore bosses when on the lifter is on the cam base circle. First, don't use more than .380" total cam lift when using a full size lobe. Second, don't use small base circle camshafts. If you must, then verify the tie bar to lifter boss clearance when the lifter is on the base circle and relieve the top of lifter bore bosses where necessary.

Do your GM LS drop-in lifters (GP1012) work in small block Chevy V8 engines that were originally equipped with roller lifters?

No, we don't recommend it. Our competitors use a compromise design to fit both engines. We don't. Since the engine lifter bore/oil feed geometries are much different between those two engines, we optimized the lifter design for each engine configuration.

No, we don't recommend it. Our competitors use a compromise design to fit both engines. We don't. Since the engine lifter bore/oil feed geometries are much different between those two engines, we optimized the lifter design for each engine configuration.

- GP1012 - 1997-Up GM Gen III & IV LS, Gen V LT V8

- GP1013 - 1987-2002 Chevrolet 305-350 V8 (Originally equipped with roller lifters)

Will your Chevrolet retrofit lifters fit late model or aftermarket blocks with tall lifter bores meant for stock hydraulic roller lifters?

Yes, they will fit the .300" tall applications. We designed the retrofit lifter bodies to be tall enough for the late model and aftermarket blocks.

Yes, they will fit the .300" tall applications. We designed the retrofit lifter bodies to be tall enough for the late model and aftermarket blocks.

Some Chrysler B V8 and Ford FE V8 engines oil through the pushrods while others don't. Will your Chrysler B and Ford FE lifters work with both types of oiling?

Yes, they will. Just be sure to use the appropriate type of pushrod for the engine as it came from the factory.

Yes, they will. Just be sure to use the appropriate type of pushrod for the engine as it came from the factory.

Installation Information

When I installed your retrofit lifters in my engine, it looks like the lifters won't work properly because they come out of the top of the lifter bores too far at maximum lift. What should I do?

Retrofit lifters are designed to allow the use of a roller camshaft in engines that were intended to use flat-faced lifters and camshafts. Our lifters are designed to function properly in the applications listed for them. But, there are some engines that are notorious for causing problems. Two examples are the early Chrysler LA V8 and the Gen V big block Chevrolet V8. Due to the block design and production casting/machining variations, there may be excessive core shift in the casting or extra deep countersinks on the top of some or all of the bores. This can resulting in the oil relief band or oil feed holes on the lifter becoming close to being exposed when the lifter is at maximum lift, potentially bleeding off engine oil pressure.

The best solution is to contact your camshaft supplier and ask them to reduce the size of the lobes by regrinding the camshaft. That will drop the maximum height of the lifter in the bore without sacrificing valve lift. Be sure that your camshaft grinder verifies that sufficient lobe hardness remains after regrinding. if regrinding your camshaft isn't an option, your block may not be suitable for retrofit lifters and can only be used with flat faced lifters.

Retrofit lifters are designed to allow the use of a roller camshaft in engines that were intended to use flat-faced lifters and camshafts. Our lifters are designed to function properly in the applications listed for them. But, there are some engines that are notorious for causing problems. Two examples are the early Chrysler LA V8 and the Gen V big block Chevrolet V8. Due to the block design and production casting/machining variations, there may be excessive core shift in the casting or extra deep countersinks on the top of some or all of the bores. This can resulting in the oil relief band or oil feed holes on the lifter becoming close to being exposed when the lifter is at maximum lift, potentially bleeding off engine oil pressure.

The best solution is to contact your camshaft supplier and ask them to reduce the size of the lobes by regrinding the camshaft. That will drop the maximum height of the lifter in the bore without sacrificing valve lift. Be sure that your camshaft grinder verifies that sufficient lobe hardness remains after regrinding. if regrinding your camshaft isn't an option, your block may not be suitable for retrofit lifters and can only be used with flat faced lifters.

How much spring pressure should I use with your lifters?

As a general rule, we recommend using the least amount of spring pressure to achieve the desired performance results. Excessive spring pressure can cause heat and premature wear on the entire valve train, including the lifters. Extra spring pressure is often used as a band aid to mask other valve train problems caused by mis-matched components or overly aggressive cam shapes.

For most street/strip applications, we recommend the following:

Valve Closed (Seat Pressure) 140-160 lbs.

Valve Open Pressure 360-400 lbs.

It's not uncommon for our customers to increase the spring pressure for high performance applications to the following:

Valve Closed (Seat Pressure) 180-200 lbs.

Valve Open Pressure 460-480 lbs.

While more spring pressure may add extra rpms and horsepower, it comes at the expense of durability, particularly for the roller bearing. Remember, the actual static force on the lifter is the spring pressure multiplied by the rocker arm ratio. For example, on a big block Chevy, if the valve open pressure is 500 lbs., the actual static force on the lifter is 500 x 1.7, or 850 lbs. So, at low engine speeds, when there’s often inadequate lubrication, the static force on the lifter roller bearing is significant.

As a general rule, we recommend using the least amount of spring pressure to achieve the desired performance results. Excessive spring pressure can cause heat and premature wear on the entire valve train, including the lifters. Extra spring pressure is often used as a band aid to mask other valve train problems caused by mis-matched components or overly aggressive cam shapes.

For most street/strip applications, we recommend the following:

Valve Closed (Seat Pressure) 140-160 lbs.

Valve Open Pressure 360-400 lbs.

It's not uncommon for our customers to increase the spring pressure for high performance applications to the following:

Valve Closed (Seat Pressure) 180-200 lbs.

Valve Open Pressure 460-480 lbs.

While more spring pressure may add extra rpms and horsepower, it comes at the expense of durability, particularly for the roller bearing. Remember, the actual static force on the lifter is the spring pressure multiplied by the rocker arm ratio. For example, on a big block Chevy, if the valve open pressure is 500 lbs., the actual static force on the lifter is 500 x 1.7, or 850 lbs. So, at low engine speeds, when there’s often inadequate lubrication, the static force on the lifter roller bearing is significant.

What weight and type of oil is best for your lifters?

Our lifters will work well with most high quality conventional motor oils. It's not recommended to use light weight oils except in cold climates. Based on our past experience, mineral oils seem to result in slightly quieter operation, but ultimately your choice of oil should be dictated by the overall engine requirements.

Some other lifter manufacturers offer "slow" leakdown lifters for which they recommend the use of oil of a specific kinematic viscosity. We have no information to validate or disprove the claimed lifter performance benefits. However, we have heard reports of problems attributed to that approach. Our lifters are designed and component-matched to work properly with conventional weight motor oils, since we continue to believe that the lubrication needs of the entire engine, not just the lifters, should determine the correct engine oil to use.

Our lifters will work well with most high quality conventional motor oils. It's not recommended to use light weight oils except in cold climates. Based on our past experience, mineral oils seem to result in slightly quieter operation, but ultimately your choice of oil should be dictated by the overall engine requirements.

Some other lifter manufacturers offer "slow" leakdown lifters for which they recommend the use of oil of a specific kinematic viscosity. We have no information to validate or disprove the claimed lifter performance benefits. However, we have heard reports of problems attributed to that approach. Our lifters are designed and component-matched to work properly with conventional weight motor oils, since we continue to believe that the lubrication needs of the entire engine, not just the lifters, should determine the correct engine oil to use.

For my automotive application, what length pushrods do I need and how do I adjust the lifters?

That information is available by downloading the following document:

That information is available by downloading the following document:

| gpllc__hydraulic_lifter_installation_instructions_2017.pdf | |

| File Size: | 163 kb |

| File Type: | |

What diameter pushrods will work with Gaterman Products lifters?

Our lifters will work with pushrods having either 5/16" or 3/8" diameter ball ends.

Our lifters will work with pushrods having either 5/16" or 3/8" diameter ball ends.

How should I prepare Gaterman Products lifters for installation in my engine?

It's imperative to keep the lifters clean before they're installed in your engine. The lifters come from our factory filled with leakdown fluid and lightly oiled. If handled carefully, they can be installed as is. Soaking the lifters in clean engine oil is generally a good idea, mainly to insure the roller bearing has sufficient lubrication during initial start-up.

DO NOT:

It's imperative to keep the lifters clean before they're installed in your engine. The lifters come from our factory filled with leakdown fluid and lightly oiled. If handled carefully, they can be installed as is. Soaking the lifters in clean engine oil is generally a good idea, mainly to insure the roller bearing has sufficient lubrication during initial start-up.

DO NOT:

- Wash the lifters in solvent.

- Dis-assemble the lifters to clean them.

- Use compressed air to clean the lifters.

- Use moly-lube on the lifters or cam lobes.

- Use dirty or lint-laden rags to wipe the lifters.

When installing Gaterman retrofit lifters in my engine, which way should they face?

All of our retrofit lifters should be installed with the large diameter of the rivet and the tie bar toward the center of the engine. On the big block Chevy V8 (GP1002), the arrow on the tie bar should also be pointing up.

All of our retrofit lifters should be installed with the large diameter of the rivet and the tie bar toward the center of the engine. On the big block Chevy V8 (GP1002), the arrow on the tie bar should also be pointing up.

When adjusting my lifters for the first time, I found that one or two of the lifters were able to be collapsed by hand. Are they ok?

Yes, they are. When the lifters leave our factory, they're filled with the laboratory grade leakdown fluid, which is a thin weight derivative of kerosene. During shipment, some of that fluid, which is equivalent to a 2W oil viscosity, can leak out. This will make the lifter feel soft. If you adjust the pre-load properly, the lifter will pump up during the first few seconds of operation until it has a chance to fill with oil. The engine will initially make a clattering noise which gradually fades away.

Yes, they are. When the lifters leave our factory, they're filled with the laboratory grade leakdown fluid, which is a thin weight derivative of kerosene. During shipment, some of that fluid, which is equivalent to a 2W oil viscosity, can leak out. This will make the lifter feel soft. If you adjust the pre-load properly, the lifter will pump up during the first few seconds of operation until it has a chance to fill with oil. The engine will initially make a clattering noise which gradually fades away.

Is there a break-in procedure with hydraulic roller lifters?

Yes, there is. Even though the roller lifter is rolling rather than rubbing like a flat faced lifter, there is still a "mating" of the cam lobe face and the o.d. of the roller. Since the roller face has a spherical compound radius on it to prevent edge riding, the contact pattern between the roller o.d. and the cam lobe is actually elliptical. Even though both materials are very hard, there is still a minute amount of elasticity at the interface.

Before starting the engine, be sure both the roller assembly and the cam lobe are well coated with oil. Pre-lubing the engine prior to start-up is highly recommended to insure oil pressure is immediately available and the lifters are full of oil. Once the engine has started, keep the rpms up to at least 2000 rpm, and vary it between 1500 and 2500 for at least 15 minutes. After that, whatever "mating" of the roller-lobe interface there will be will already have occurred. You may have to vary your rpm and time somewhat to be sure the other engine wear surfaces have broken in. It's always a good idea to change the oil and filter after the break-in period.

Yes, there is. Even though the roller lifter is rolling rather than rubbing like a flat faced lifter, there is still a "mating" of the cam lobe face and the o.d. of the roller. Since the roller face has a spherical compound radius on it to prevent edge riding, the contact pattern between the roller o.d. and the cam lobe is actually elliptical. Even though both materials are very hard, there is still a minute amount of elasticity at the interface.

Before starting the engine, be sure both the roller assembly and the cam lobe are well coated with oil. Pre-lubing the engine prior to start-up is highly recommended to insure oil pressure is immediately available and the lifters are full of oil. Once the engine has started, keep the rpms up to at least 2000 rpm, and vary it between 1500 and 2500 for at least 15 minutes. After that, whatever "mating" of the roller-lobe interface there will be will already have occurred. You may have to vary your rpm and time somewhat to be sure the other engine wear surfaces have broken in. It's always a good idea to change the oil and filter after the break-in period.

Can the lifters be noisy on startup after the engine has been sitting for a while?

Yes, they definitely can. When the engine is shut off, some of the lifters may not be on the cam base circles, but may instead be on the lift portion of the lobes. If that happens, the lifter is under constant load from the valve spring holding the valve open. Eventually, the force will bleed the oil out of the lifter, resulting in clearance during the next engine re-start. The engine will clatter momentarily until the lifter refills with oil to take up the clearance. High ratio rocker arms, strong valve springs, and high lift cam lobes all contribute to this situation. In reality, the lifter wouldn't function without its ability to bleed down under load. So, there's no way to completely avoid it.

Yes, they definitely can. When the engine is shut off, some of the lifters may not be on the cam base circles, but may instead be on the lift portion of the lobes. If that happens, the lifter is under constant load from the valve spring holding the valve open. Eventually, the force will bleed the oil out of the lifter, resulting in clearance during the next engine re-start. The engine will clatter momentarily until the lifter refills with oil to take up the clearance. High ratio rocker arms, strong valve springs, and high lift cam lobes all contribute to this situation. In reality, the lifter wouldn't function without its ability to bleed down under load. So, there's no way to completely avoid it.

Buying Tips

Where can I buy Gaterman Products lifters?

We don't sell our automotive lifters direct to consumers. See our Dealers page for authorized dealers and distributors. Since some are selling our lifters under their own brand name, specify that you want Gaterman lifters, Even if your engine builder or dealer isn't listed on our dealer page, they can get our parts through one of our distributors, Consult your dealer for price and availability.

We don't sell our automotive lifters direct to consumers. See our Dealers page for authorized dealers and distributors. Since some are selling our lifters under their own brand name, specify that you want Gaterman lifters, Even if your engine builder or dealer isn't listed on our dealer page, they can get our parts through one of our distributors, Consult your dealer for price and availability.

How are Gaterman Products lifters cataloged for sale?

We sell our retrofit/tie bar lifters in sets of 16, or in pairs. As an example, a set of 16 small block Chevrolet V8 retrofit lifters is sold under part number GP1001. One pair of the same lifters is sold under part number GP1001-2. The drop-in lifters are sold in sets of 16 or as an individual lifter. As an example, a set of 16 GM LS V8 drop-in lifters is sold under part number GP1012. An individual lifter is sold under part number GP1012-1.

We sell our retrofit/tie bar lifters in sets of 16, or in pairs. As an example, a set of 16 small block Chevrolet V8 retrofit lifters is sold under part number GP1001. One pair of the same lifters is sold under part number GP1001-2. The drop-in lifters are sold in sets of 16 or as an individual lifter. As an example, a set of 16 GM LS V8 drop-in lifters is sold under part number GP1012. An individual lifter is sold under part number GP1012-1.

I saw some retrofit lifters on Ebay for under $200 a set that looked a lot like yours. Are those Gaterman Products lifters?

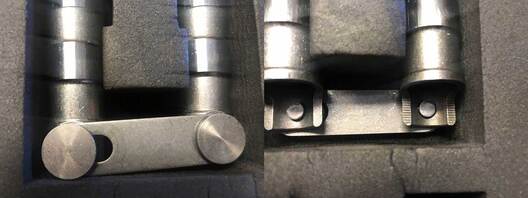

No, they're not. There are copy-cat lifters selling online for very low prices that are often mistaken for ours. We've heard of multiple engine failures caused by those lifters, which doesn't happen with ours. If the lifters look like the pictures below, they're not Gaterman Products lifters. If you have any question about which ones you're buying, contact us first.

No, they're not. There are copy-cat lifters selling online for very low prices that are often mistaken for ours. We've heard of multiple engine failures caused by those lifters, which doesn't happen with ours. If the lifters look like the pictures below, they're not Gaterman Products lifters. If you have any question about which ones you're buying, contact us first.

There are lifters shown online under the name Gatorman Retrofit Hydraulic Roller Lifters selling at a reduced price. The name is spelled similar to yours, but it's not exactly the same. Are those your lifters?

We don't sell to the online dealer offering lifters under the brand name Gatorman. We've asked our major distributors and they aren't selling to them either. We don't know whose lifters they are, but they aren't Gaterman Products lifters. So, if you want genuine Gaterman lifters, stay away from them.

We don't sell to the online dealer offering lifters under the brand name Gatorman. We've asked our major distributors and they aren't selling to them either. We don't know whose lifters they are, but they aren't Gaterman Products lifters. So, if you want genuine Gaterman lifters, stay away from them.

Do Gaterman Products lifters have a warranty?

Yes, they do. Please refer to the document below.

Yes, they do. Please refer to the document below.

| gaterman_products_2017_consumer_automotive_lifter_warranty_policy_1.pdf | |

| File Size: | 117 kb |

| File Type: | |